Fékk þetta lánað af e30zone...Hi guys, new on these boards, but not new to BMW circles. I finally got the M20 flow testing completed I thought I would Share.

Having been involved in a number of 4 valve pent roof high performance developments that are currently in production it was a nice change undertaking the evaluation of some old style 2 valve cylinder heads and comparing them to some benchmark values I have.

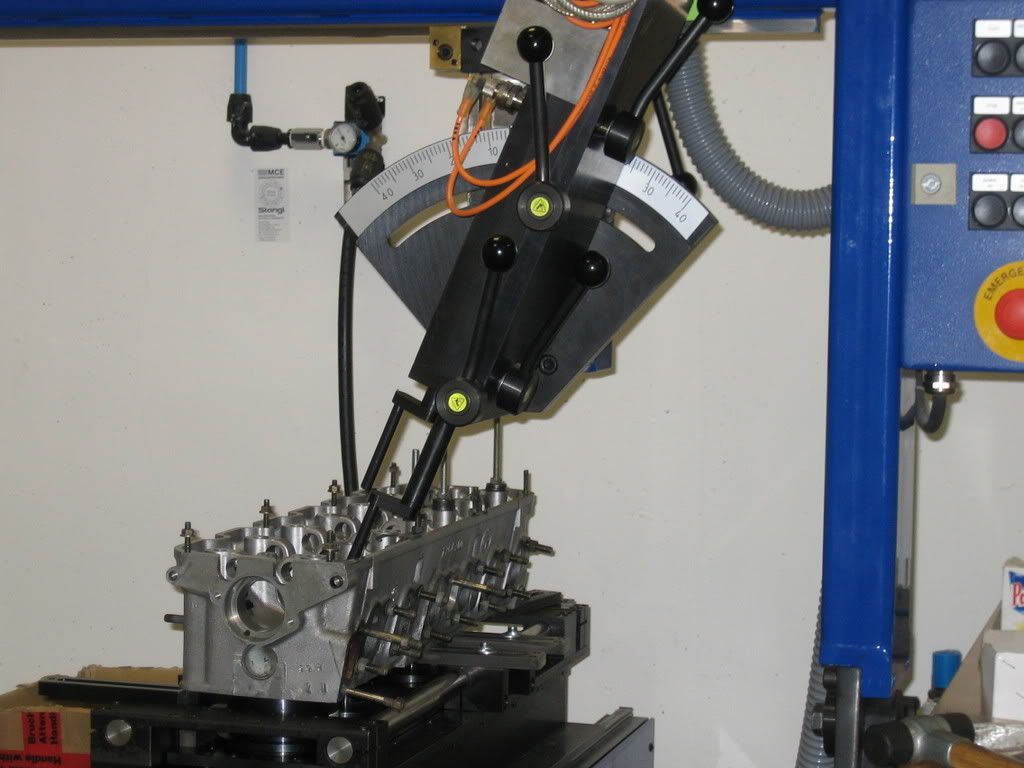

I've used an AVL Tippelman flow bench, which cost in the order of 300,000 Euros and cost 7500 euros to calibrate/validate a few months ago

The mammoth flow bench measures flow and motion, broken down into the components of swirl and tumble.

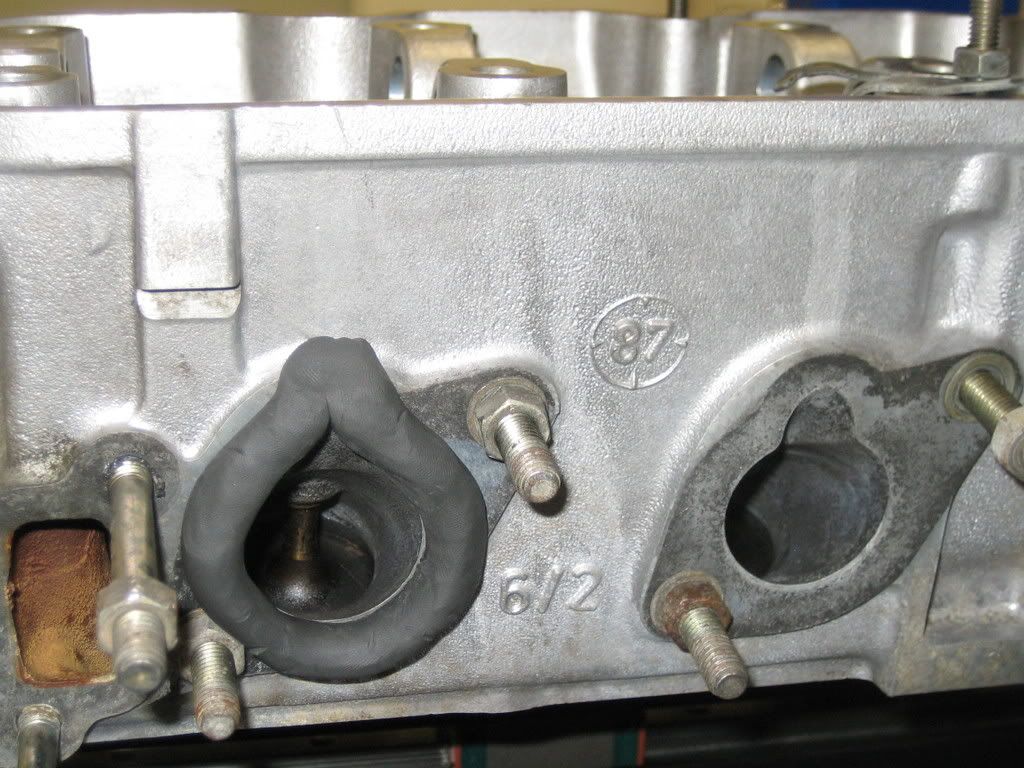

The BMW M20 series use a very shallow angle hemi (2 X 22 degrees) with slightly offset valves- BMW called it their 'Drei Kugel wirbel kammer' which is a fancy way of saying it generates alot of motion. During testing I found the amount of motion generated for the level of flow impressive.

These engines were fitted in late 1970s and 1980s BMW 3 series, and they produce more motion in swirl than a modern E90 (expected) but suprisingly more Tumble also. This is suprising as Motion is what modern car manufacturers use indirectly in their armory to meet emission for rapid catalyst light off and in cylinder EGR tolerance/charge dillution. I would put money on the fact that the M20 and M30 BMWs produced alot more in cylinder motion while disturbing outright flow little, when compared to era contemporaries, such as the Alfa V6 2 valve, the Porsche 911, the Mercedes M110 (2.8 litre twin cam) which are all quiescent with the valves on the centreline of the combustion system.

For the intake I moulded a bell mouth to minimise intake losses/invalidating the results

For the Exhaust I made up a diffuser pipe for the same reason

Automated valve opener makes my job easy

In terms of pressure drop, I commnly used the OEM industry standard of 50 mbar.

This equates to about 20 inches of water. I'm in the process of buying a small Superflow 120 and wanted to validate it against this AVL rig. I measured the same cylinder head for both intake and exhaust at pressure drops ranging from 10 inches of water all the way up to 33 inches and compared the flow coefficient results. This is perhaps subject for another post, but I found that there was some difference with these cylinder heads at higher pressure drops versus lower mainly at high valve lifts/high flow rates (above 12mm of lift). This may be different if testing an engine of a bigger cylinder capacity/higher flow capability.

All in all there are 3 variants of the BMW M20 series, which affcionados will be aware of, the 1970s 323i head-casting number 1264200

the 1980s 323i, head casting number 1277731

and the mid to late 1980s 325i casting number 1705885. Each of these I tested and changed the bore sizes significantly to see the sensitivity to 'bore shrouding' [ When involved in the Jaguar and Aston Martin V8 development I found those engines very sensitive to bore size-effecting flow significantly]. The M20 engine isn't sensitive to bore shrouding. This is probably because

1) the engine is a 2 valve so flow from another intake valve doesnt shroud

2)the included valve angle is big enough to not interact with the side of the bore

3)The valves, although big (0.5 Bore intake), could probably be made bigger for the bore size

With this in mind, if tuning the M20 I would try to take advantage of this and fit larger valves. Only problem being is that if 45mm inlets are fitted and the inlet valve is lifted over 2mm at TDC with conventional cams the intake and exhaust usually clash. I'm currently looking into this issue

And finally let me post the results

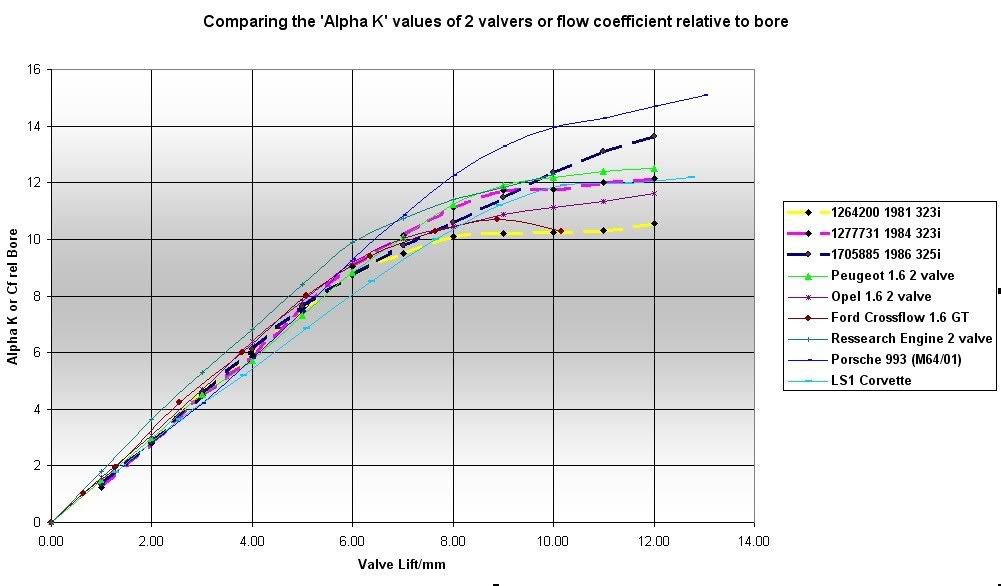

'Alpha K' or Flow Coefficient relative to bore size shows how good an engine is at filling its cylinder. Unlike CFM you can compare engine to engine, regardless of capacity. In the comparison plots I've show some notably good flowing 2 valvers (including the LS1 Vette engine). For the design compromises involved the LS1 is very repsectable but gets most of its flow through sheer size of the ports. Unfortunately this means that the gas velocities are quite low. These's always a compromise of gas velocity, in cylinder motion and outright flow. The Peugeot is 2 valver is the one that suprised me the the most as that engine I believe doesn't have inclined/angled valves at all. I've also included some old legends such as the 1.6 GT Ford Cross flow engine from the 1970s for reference. Out of the BMW stuff tested, I would say that the 1277731 BMW head cuts it pretty well compared to the few 2 valvers out there today and the 1705885 325i is quite good indeed. The Porsche 911/993 (last of the air cooled) show what is possible for a road engine. This head doesn't produce much in cylinder motion at all but at high lift flows almost like a reasonable 4 valver (it's a relatively large angle classical hemi). From my experience, I would say that at high valve lifts an 'Alpha K' of 16% represents an exceptionally good 2 valve head feeding a cylinder. 11-12% is pretty good going at high lifts, and anything around the 10% is a well developed road port for good cylinder filling.

Finally, I'm showing flow coefficient relation to the Inner seat diameter.

This figure ignores how well a port can feed a cylinder and purely focuses on just how good that port is when considering the ISD size. Both the '731' and '885' ports are very accomplished and compare favourably even with a modern LS1 cylinder head. It also outlines the inferiority in this company of the '200' early 3 series port, and should hopefully bring home the folley in people who continue to pedal these cylinder heads for high performance/high capacity M20 conversions. Forget it. The '885' head casting is the undisputed best. Just to keep an eye on port velocities however at 6000 rpm peak powerspeed and taking into account the cylinder capacity, I calculate the following for the '200', '731' and '885' respectively:93m/s, 76m/s and 77 m/s the last two are lower than I had expected. I usually design ports for a velocity in the 'trouser leg' of over 90 m/s. You can move the compromise towards flow perhaps (making them bigger), if the design of the port won't deliver. The worst aspect of the M20 is the low roof of the port close to the valve seat.

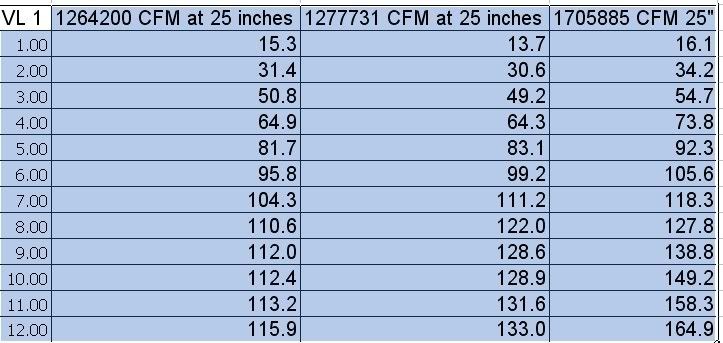

And for all those who are used to CFM, I've converted my figures to CFM- using 25 inches of water as a reference: